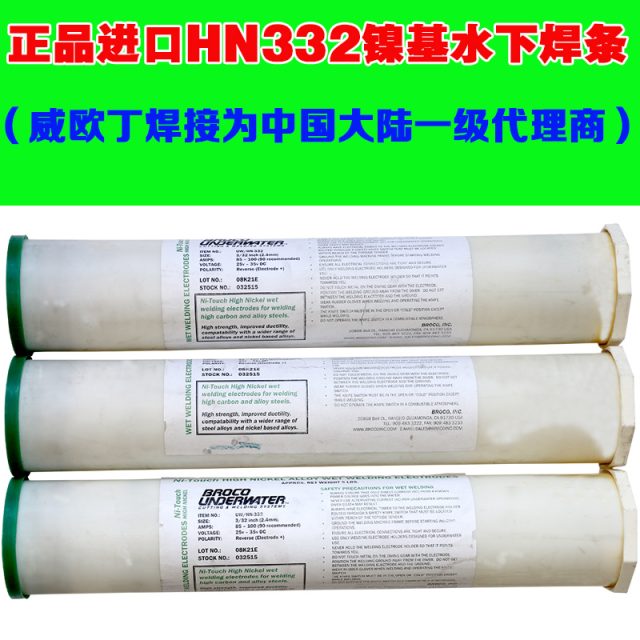

进口BROCO镍基水下焊条 Ni-Touch HN332真正的湿法水下焊接用镍基焊条

品牌:BROCO

产地:美国

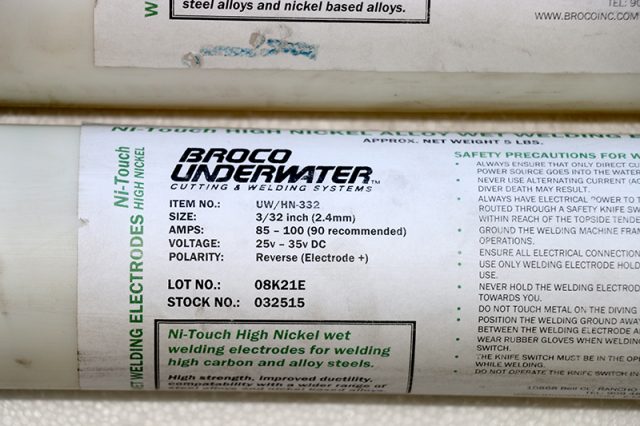

型号:Ni-Touch系列下的 UW/HN332

规格:3/32″(相当于2.38毫米直径)

包装:5磅/包 (约75根每包)

图片:

介绍

Broco公司开发的Ni-Touch™镍湿式焊条可以在水下对碳和高强度钢进行湿法焊接,而通常需要更昂贵的干腔焊

接。镍基湿法水下焊条Ni-Touch系列下的HN332自1980年代早期以来就被美国海军用于有选择性的船舶维修。现在Broco为客户研究并提供了一种改

进的行业领先的镍基水下焊条,可以产生更少的气孔,并允许在架空位置进行更深的焊接。HN332镍基水下焊条适用于全位置焊接,也可以进行角焊位置焊接。

高抗拉钢通常含有碳含量和碳当量,因此使用碳钢专用的水下焊条焊接会由于淬火硬化组织内的氢脆而导致热影响区开裂。通过Ni-Touch系列下的HN332镍基水下焊条可以减少氢的影响,并能成功地在水下进行湿法焊接,涉及范围广泛 的中、低、高碳钢,包括用于碳当量超过0.50%的海军舰艇的HY-80淬火钢和回火钢。

现如今BROCO拥有的Ni-Touch系列下的HN332镍基水下焊条技术可以到水深 33英尺的地方。Ni-Touch系列下的HN332镍基水下焊条的直径只有3/32”。

试验结果超过了美国焊接协会B级水下湿焊规范D3.6的要求。满 足更严格的要求海军的军舰技术手册NSTM 074。通常,在焊接条件下,HN332镍基水下焊条焊接焊缝金属的屈服强度超过70ksi,拉伸强 度超过80ksi。

Broco’s Ni-Touch™ nickel wet welding electrode was developed to allow underwater wet welding of carbon and high tensile steels which would normally require the use of more expensive dry chamber welding. Nickel wet welding electrodes have been used by the U.S. Navy since the early 1980s for selective ship repairs. Now Broco® brings customers an improved industry-leading nickel electrode which produces welds with less porosity and allows deeper welding in the overhead position. Ni-Touch™ electrode is appropriate for all position groove and fillet welds.

High tensile steels generally have carbon contents and carbon equivalents such that welding using carbon steel wet welding electrodes would result in cracking in the heat-affected-zone due to hydrogen embrittlement within a quench-hardened microstructure. With Ni-Touch™ the nickel electrode mitigates the effect of hydrogen and results in successful underwater wet welds involving a broad range of high carbon equivalent steels, including HY-80 quenched, and tempered steel used in Naval ships with carbon equivalents exceeding 0.50 percent.

About Ni-Touch™:

- Presently qualified to a water depth of 33 feet.

- Ni-Touch electrodes are only available in size 3/32″ diameter.

- Test results exceed the requirements of the American Welding Society Specification D3.6 for Class B underwater wet welds.

- Meets the more stringent requirements of the Navy’s Naval Ship Technical Manual NSTM 074.

- Typically, yield strengths exceeding 70 ksi and tensile strengths exceeding 80 ksi can be expected from the nickel weld metal in the as-welded condition.

威欧丁(天津)焊接技术有限公司版权所有。转载请注明焊接技术网及原文地址。